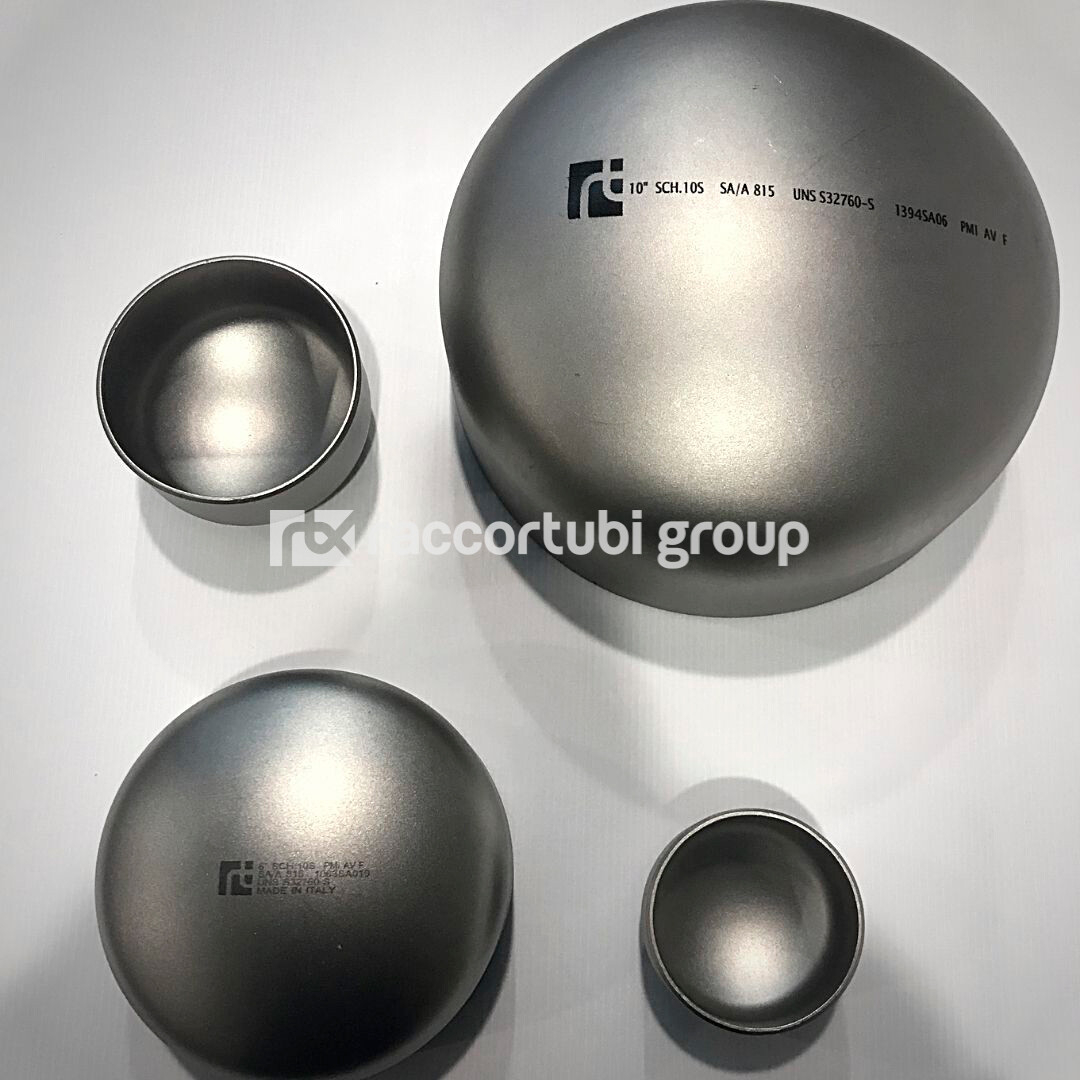

Caps

In our wide variety of butt weld fittings, you can’t miss caps!

The wide range of materials we offer – from austenitic stainless steel, to super austenitics, to Titanium, to Nickel alloys, etc. – meets the demands of the most critical applications, from the chemical industry, to petrochemicals, offshore platforms, shipbuilding, energy production.

Our caps, available from 1/2″ to 16″, are manufactured in accordance with current technical standards (ASTM / ASME / ANSI) and quality, in a wide range of thicknesses and grades.

As distributors, we are also able to supply a full range of caps, in terms of diameter, schedule and material.

Want to know more? Fill out the form and send us your request!

Technical features

Thickness

Sch10, Sch20, Sch30, STD, Sch40, Sch60, XS, Sch.80, Sch.100, Sch.120, Sch.140, Sch.160, XXS (ASME B36.10) / Sch.5S, Sch.10S, Sch.40S, Sch.80S (ASME B36.19) / thickness on request (nominal thickness / minimum thickness / particular tolerances)

Grades

austenitic stainless steel (WP 304/304L; WP316/316L; WP 321/321H; WP 304/304H; WP 347/347H), Duplex and Super Duplex (UNS S31803/S32205; UNS S32760; UNS S32750), Nickel alloys (UNS N06625; UNS N08825), Titanium (TI GR 2), 6MO (UNS S31254), UREA (WP 316L UG; 25.22.2 / UNS S31050)

Applications

shipyards, nuclear, chemical, pharmaceutical, desalination, fertilizers, green chem, oil&gas, offshore, petrochemical, renewable energy (solar, wind farm, geothermal, etc.), water treatment, hydrogen, food&beverage etc.

Technical standards

ASTM/ASME A403/A403M, A815/A815M, B363, B366/B366M

Dimensions to ANSI B16.25

From production and from stock

Cold forming

Seamless